glass

Research and Application of Innovative Zirconia Sand Products

When it comes to industrial materials, many laypeople might find the topic boring, but there are actually quite a few intricacies to it. Take zirconia, for example. In the past, people might have only considered it to be used for things like ceramic knives and dentures, something hard and shiny. But for those of us involved in materials research and development and industrial applications, it’s a treasure. The innovative zirconia sand products that have emerged in recent years, in particular, have truly solved significant problems and offer dazzling application prospects.

I remember attending an industry exhibition two years ago and chatting with a veteran engineer who had worked in refractory materials for decades. He slapped his thigh and said, “Hey, bro, you don’t understand! The smelting industry now places incredibly high demands on materials! Temperatures are getting higher and higher, and the environment is becoming increasingly harsh. Traditional materials can’t handle it. Take zirconia, for example. Everyone knows it’s great—high-temperature resistant and chemically stable. But zirconia sand produced using traditional processes is either lacking in purity, poor particle uniformity, or instability. It’s also incredibly expensive, making it a pain to use. Often, it’s like ‘the will is there, the ability is not there.'”

He hit the nail on the head. This is precisely the original intention of our innovative zirconia sand research and development—isn’t it to overcome these old challenges?

So where exactly does innovation lie? Let me explain.

First, the “core” must change. Previous zirconia had a problem: its crystal structure was unstable. When the temperature fluctuated, it could “fight” internally, creating microcracks. Over time, performance deteriorated. Our new approach involves major overhauls in formulation and processing. By introducing more advanced stabilizers, such as yttrium, combined with ultra-high-temperature sintering and more sophisticated crushing and classification techniques, we’ve achieved this remarkable product: “partially stabilized zirconia.” Put another way, it’s like building a “steel skeleton” within the zirconia particles, ensuring they’re hard when needed and ductile when needed, unlike the brittle, easily damaged material of the past. Furthermore, purity is steadily increasing, with impurity levels kept to an extremely low level.

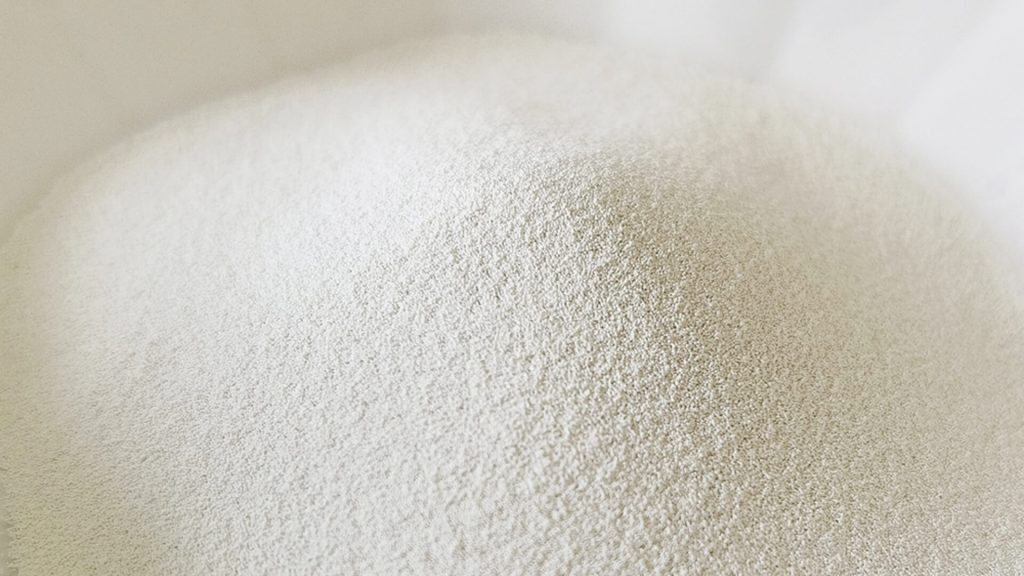

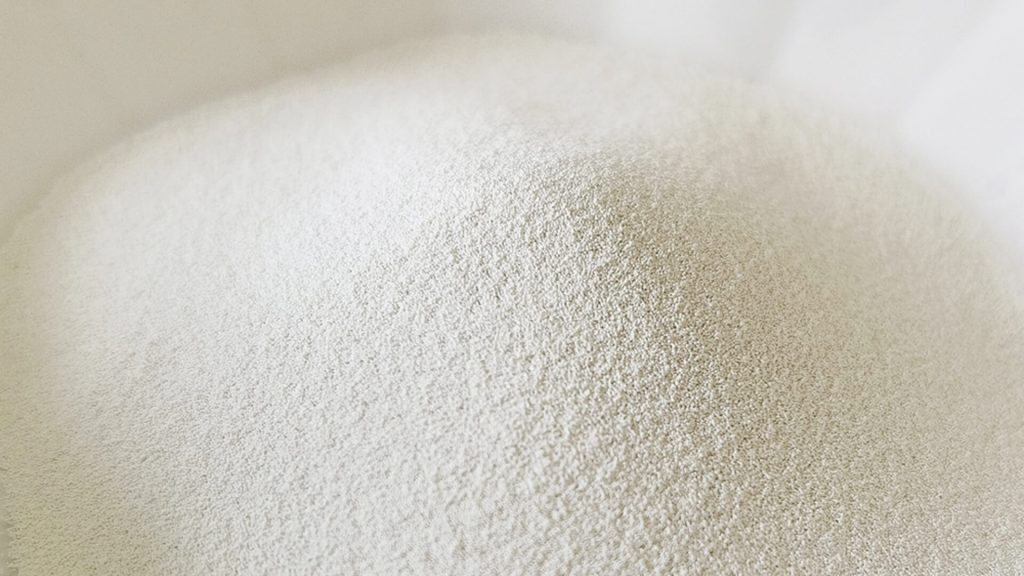

Secondly, attention must also be paid to appearance and shape. Innovative zirconia sands place particular emphasis on appearance—not just for beauty contests, but in terms of particle morphology and size distribution. The previously angular, unevenly sized, “coarse” particles were a disaster for precision applications. Now, through sophisticated processes like air jet milling and centrifugal classification, we can produce nearly spherical zirconia micropowders with extremely uniform particle sizes. Grab a handful and it feels like the finest flour, yet its hardness is incredibly high. This uniformity offers enormous benefits: whether used as a coating or an abrasive, the results are stable and uniform, without uneven application.

Talking big is useless; development must be put to practical use. These innovative zirconia sands are now highly sought-after in various high-end fields.

First and foremost, precision casting is crucial, especially for thin-walled, complex superalloy parts like aircraft engine blades and gas turbine blades. Casting temperatures reach over 1,000 degrees Celsius, placing extremely high demands on the mold shell material. Topcoats made with this new zirconia sand offer excellent stability and a matching thermal expansion coefficient. This significantly improves the surface finish of castings, making defects like sand pick-up and burrs virtually invisible, significantly reducing the cost of subsequent finishing. Experienced craftspeople say, “Using this new sand, the work is truly stunning!”

Another application is high-end grinding and polishing. Our mobile phone glass, camera glass, and various semiconductor wafers require incredibly smooth surfaces; even the slightest scratch will result in scrapping. New zirconium oxide micropowder, with its high hardness, uniform particle size, and excellent chemical and mechanical properties, is a highly effective polishing fluid. The removal rate is precisely controlled, and scratch resistance is minimal, achieving a truly smooth surface at the nanoscale or even atomic level. Simply put, your phone screen feels so smooth thanks to it.

There’s also thermal barrier coatings. How can aerospace engines and gas turbines withstand such grueling temperatures? Key components are sprayed with a “thermal insulation jacket.” One of the primary materials used in this jacket is zirconium oxide-based ceramics. Innovative zirconium oxide sand, with its excellent high-temperature resistance and phase stability, is the core raw material for preparing these top-tier coating powders, which are directly related to engine efficiency and lifespan.

In addition, it can be found in structural ceramics for harsh environments, advanced refractories, and even medical biomaterials. Its applications are expanding.

In the future, I believe the path for innovative zirconia sand will be even broader. With the rapid advancements in industries like photovoltaics, semiconductor chips, and aerospace, the performance requirements for materials will only become increasingly demanding. Zirconia sand products with purer, finer, more uniform properties, and more controllable performance will undoubtedly be developed. Perhaps one day, it will shine in areas we can’t even imagine right now.

So, don’t underestimate these tiny grains of sand. They hold immense wisdom and can power major industries. The value of innovation lies in unleashing the full potential of a material to meet the demanding demands of our times.

So where exactly does innovation lie? Let me explain.

First, the “core” must change. Previous zirconia had a problem: its crystal structure was unstable. When the temperature fluctuated, it could “fight” internally, creating microcracks. Over time, performance deteriorated. Our new approach involves major overhauls in formulation and processing. By introducing more advanced stabilizers, such as yttrium, combined with ultra-high-temperature sintering and more sophisticated crushing and classification techniques, we’ve achieved this remarkable product: “partially stabilized zirconia.” Put another way, it’s like building a “steel skeleton” within the zirconia particles, ensuring they’re hard when needed and ductile when needed, unlike the brittle, easily damaged material of the past. Furthermore, purity is steadily increasing, with impurity levels kept to an extremely low level.

Secondly, attention must also be paid to appearance and shape. Innovative zirconia sands place particular emphasis on appearance—not just for beauty contests, but in terms of particle morphology and size distribution. The previously angular, unevenly sized, “coarse” particles were a disaster for precision applications. Now, through sophisticated processes like air jet milling and centrifugal classification, we can produce nearly spherical zirconia micropowders with extremely uniform particle sizes. Grab a handful and it feels like the finest flour, yet its hardness is incredibly high. This uniformity offers enormous benefits: whether used as a coating or an abrasive, the results are stable and uniform, without uneven application.

Talking big is useless; development must be put to practical use. These innovative zirconia sands are now highly sought-after in various high-end fields.

First and foremost, precision casting is crucial, especially for thin-walled, complex superalloy parts like aircraft engine blades and gas turbine blades. Casting temperatures reach over 1,000 degrees Celsius, placing extremely high demands on the mold shell material. Topcoats made with this new zirconia sand offer excellent stability and a matching thermal expansion coefficient. This significantly improves the surface finish of castings, making defects like sand pick-up and burrs virtually invisible, significantly reducing the cost of subsequent finishing. Experienced craftspeople say, “Using this new sand, the work is truly stunning!”

Another application is high-end grinding and polishing. Our mobile phone glass, camera glass, and various semiconductor wafers require incredibly smooth surfaces; even the slightest scratch will result in scrapping. New zirconium oxide micropowder, with its high hardness, uniform particle size, and excellent chemical and mechanical properties, is a highly effective polishing fluid. The removal rate is precisely controlled, and scratch resistance is minimal, achieving a truly smooth surface at the nanoscale or even atomic level. Simply put, your phone screen feels so smooth thanks to it.

There’s also thermal barrier coatings. How can aerospace engines and gas turbines withstand such grueling temperatures? Key components are sprayed with a “thermal insulation jacket.” One of the primary materials used in this jacket is zirconium oxide-based ceramics. Innovative zirconium oxide sand, with its excellent high-temperature resistance and phase stability, is the core raw material for preparing these top-tier coating powders, which are directly related to engine efficiency and lifespan.

In addition, it can be found in structural ceramics for harsh environments, advanced refractories, and even medical biomaterials. Its applications are expanding.

In the future, I believe the path for innovative zirconia sand will be even broader. With the rapid advancements in industries like photovoltaics, semiconductor chips, and aerospace, the performance requirements for materials will only become increasingly demanding. Zirconia sand products with purer, finer, more uniform properties, and more controllable performance will undoubtedly be developed. Perhaps one day, it will shine in areas we can’t even imagine right now.

So, don’t underestimate these tiny grains of sand. They hold immense wisdom and can power major industries. The value of innovation lies in unleashing the full potential of a material to meet the demanding demands of our times.